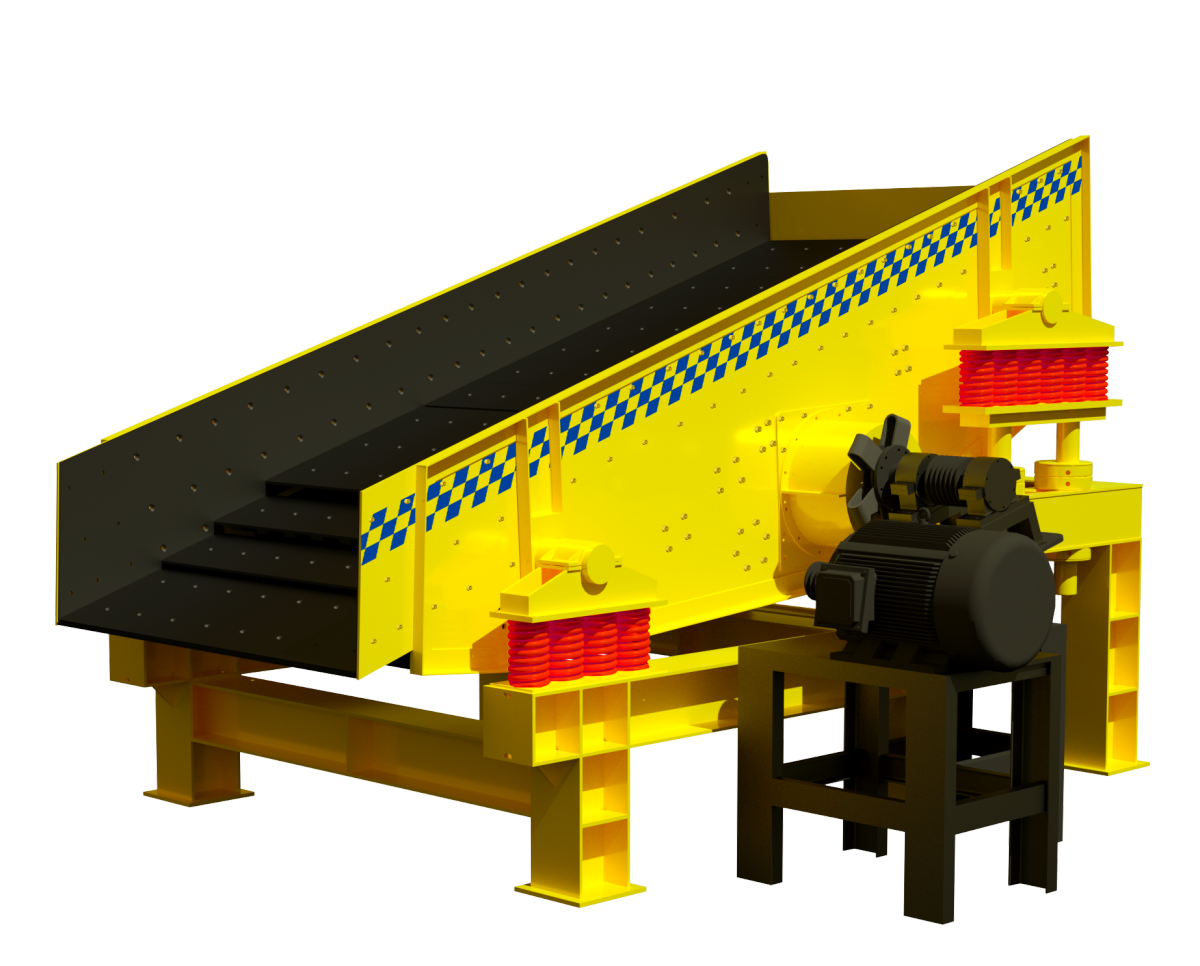

ZSW Vibration feeder

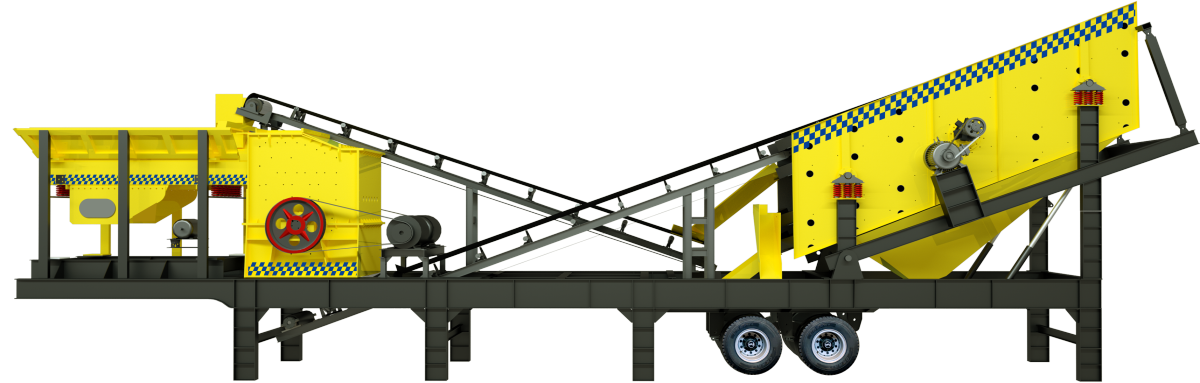

ZSW Vibrating feeder is used to feed block and granular materials uniformly, regularly and continuously from the storage bin in to stone crushers. Also it could separate the raw materials primarily by grate plate.

Feed size : < 800mm

Power : 9-37kw

Capacity : 60-680 ton/hour

What is vibrating feeder?

Vibrating feeder is used to feed rocks to primary crushing equipment continuously and evenly in the sand and gravel production line to avoid blockage of the crusher receiving port. In the production process, it can feed the lumpy and granular materials from the storage bin to the receiving device continuously, evenly and regularly, thus preventing the receiving device from dying due to uneven feeding and prolonging the service life of the equipment. Vibrating feeder is widely used in crushing and screening operations in metallurgy, coal mining, building materials, chemical industry, abrasives, mineral processing and other industries.

How to choose vibrating feeder?

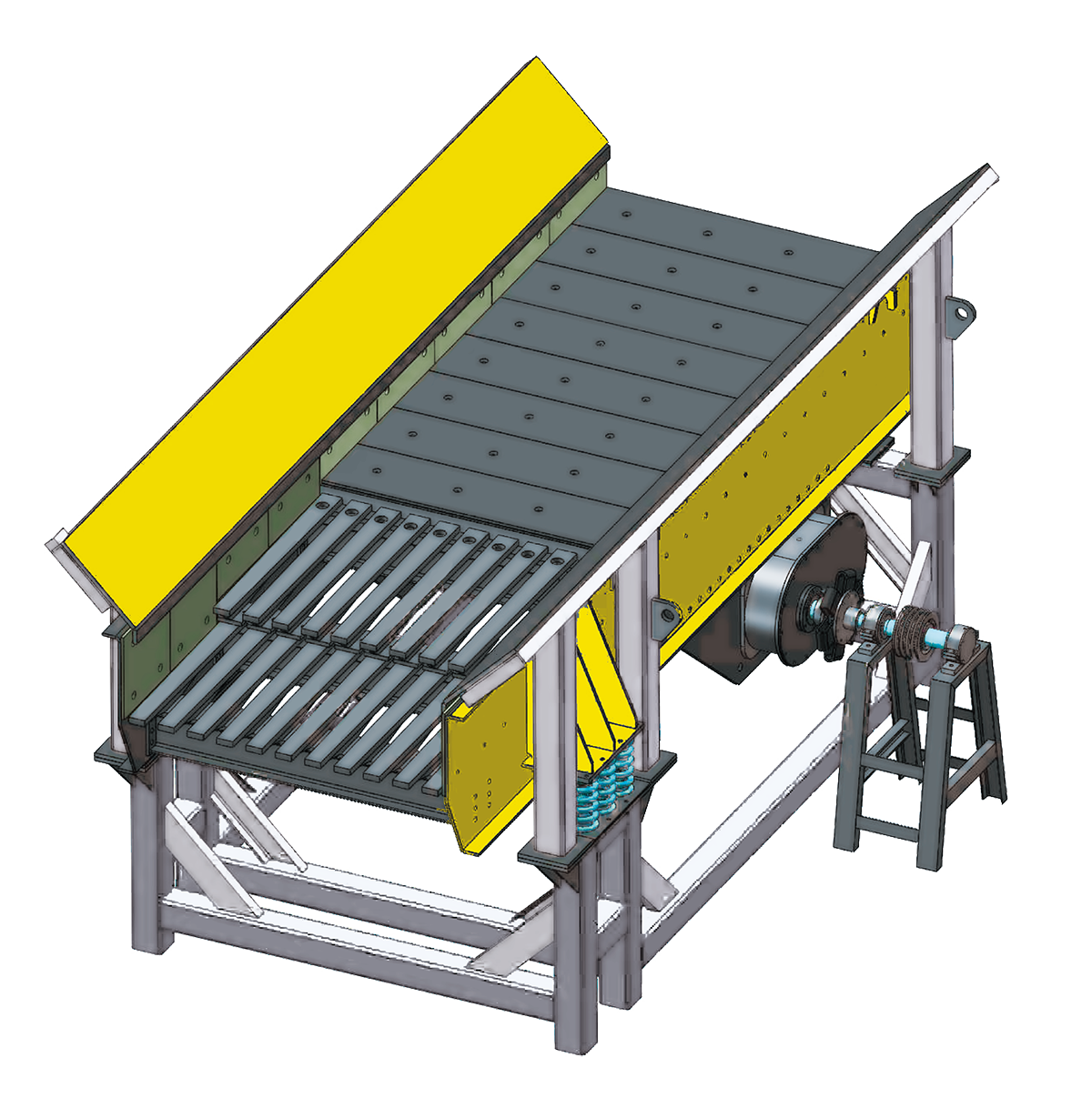

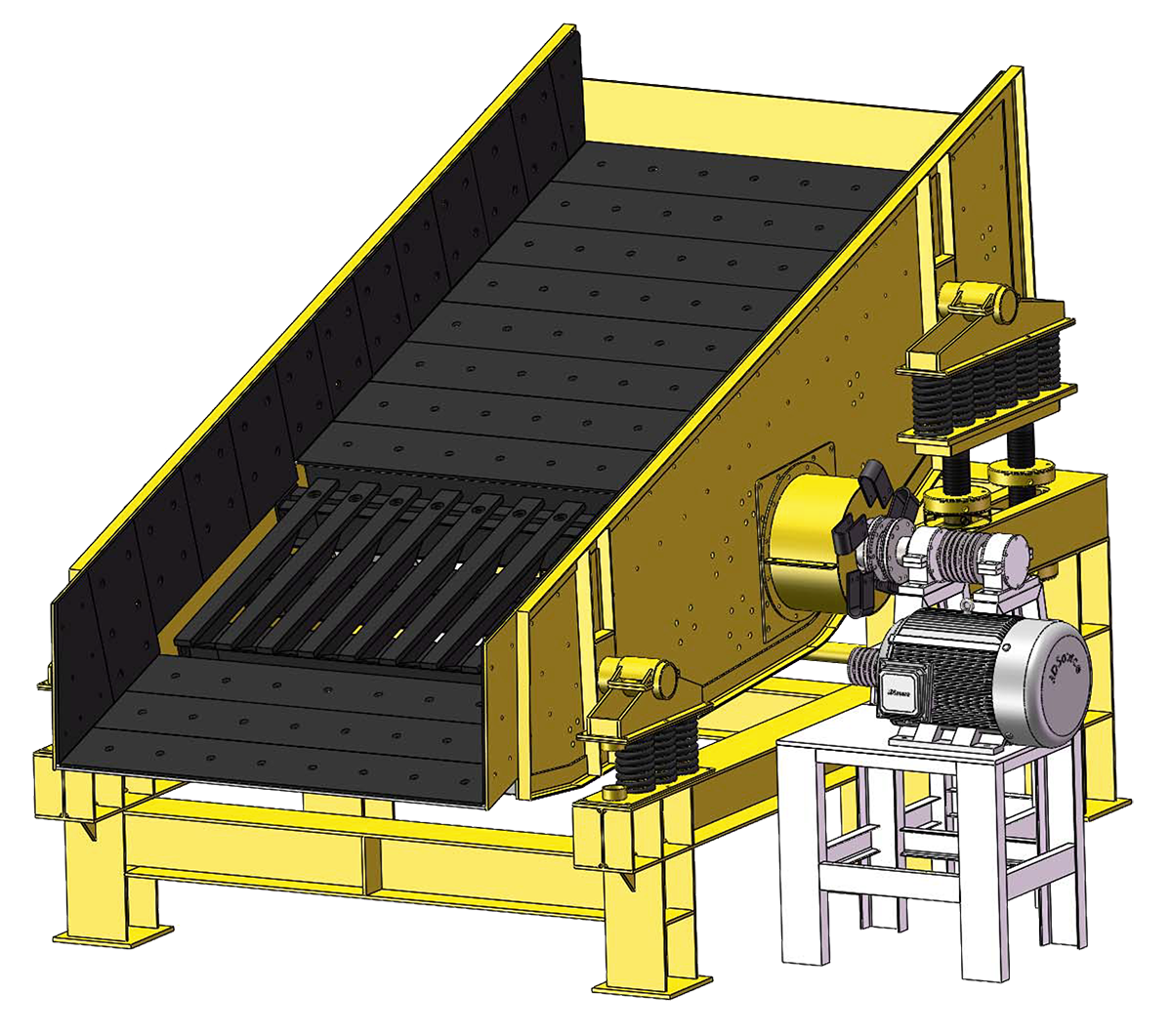

1.Vibrating feeders have steel plate structure and grate structure. The vibrating feeder with steel plate structure feeds all materials evenly into the crushing machine. It is mostly used in sand and gravel production plant.

2. Grate type vibrating feeder has a grading function and adjustable gap on the feeding surface near the discharge end, so it can separate the soil and fine-grained materials while feeding. This will improve primary crusher’s crushing efficiency.

3. Small vibrating feeder is used to uniformly, continuously or quantitatively feed blocky, granular and powdery materials from the storage bin or other storage equipment to the receiving equipment. It is suitable for automatic batching, quantitative packaging and automatic control.

4. The vibrating feeder produced by QDWL Machinery has features of stable vibration, reliable operation, low noise, low energy consumption, convenient equipment adjustment and installation. It can adopt a closed structure body to prevent dust pollution.

High Quality

Stable amplitude, reliable operation, and strong adaptability to a variety of materials.

Customized Design

Special grid design can prevent material blockage and adjustable grid gap.

Good Performance

Use inertial vibrator as the vibration source, and there are no moving part and few wearing parts.

|

|

|

Working principle

Vibrating feeder is made of vibrating frame, spring, vibrator, motor vibrating device and motor. The vibrator consists two fixed eccentric shafts whose gears are jogged. When installation, the two gears must be jogged according to the sign. By drive of the motor, the two eccentric shafts start rotating to generate a linear huge power which forces the feeder to vibrate back and forth. Through the vibration, The materials will slip and sling on the funnel, moving forward, when the materials pass the screening part, smaller material will fall down, avoiding the further crushing, so screening purpose is reached.

TECHNICAL PARAMETERS OF ZSW SERIES LIGHT LINEAR VIBRATING FEEDER

| Model |

max feed size

(mm)

|

Feeding trough

(mm)

|

Capacity

(t/h)

|

Power

(kw)

|

Frequency (f/min) | Dimension (L*W*H)(mm) | Angle |

Amplitude

(mm)

|

| ZSW0836 | 500 | 800*3600 | 60-120 | 9 | 680 | 3600*1933*2139 | 0 | 6-9 |

| ZSW1036 | 500 | 1000*3600 | 60-160 | 11 | 680 | 3600*2133*2139 | 0 | 6-9 |

| ZSW1042 | 500 | 1000*4200 | 60-180 | 11 | 680 | 4200*2138*2139 | 0 | 6-9 |

| ZSW1236 | 500 | 1200*3600 | 80-220 | 15 | 680 | 3600*2333*2139 | 0 | 6-9 |

| ZSW1242 | 500 | 1200*4200 | 80-260 | 15 | 680 | 4200*2338*2139 | 0 | 6-9 |

| ZSW1436 | 500 | 1400*3600 | 100-320 | 15 | 680 | 3600*2558*2130 | 0 | 6-9 |

| ZSW1442 | 500 | 1400*4200 | 100-380 | 15 | 680 | 4200*2558*2139 | 0 | 6-9 |

| ZSW1636 | 500 | 1600*3600 | 120-420 | 18.5 | 680 | 3600*2758*2139 | 0 | 6-9 |

| ZSW1642 | 500 | 1600*4200 | 160-460 | 18.5 | 680 | 4200*2758*2139 | 0 | 6-9 |

| ZSW1836 | 600 | 1800*3600 | 150-480 | 22 | 680 | 3600*3038*2139 | 0 | 6-9 |

| ZSW1842 | 600 | 1800*4200 | 200-520 | 22 | 680 | 4200*3038*2139 | 0 | 6-9 |

| ZSW2036 | 700 | 2000*3600 | 280-600 | 30 | 680 | 3600*3238*2139 | 0 | 6-9 |

| ZSW2042 | 700 | 2000*4200 | 300-660 | 30 | 680 | 4200*3230*2130 | 0 | 6-9 |

TECHNICAL PARAMETERS OF ZSW SERIES HEAVY LINEAR VIBRATING FEEDER

| Model |

max feed size

(mm)

|

Feeding trough

(mm)

|

Capacity

(t/h)

|

Power

(kw)

|

Frequency (f/min) | Angle |

Amplitude

(mm)

|

| ZSW380-96 | 600 | 1000*3800 | 70-200 | 15 | 680 | 0 | 6-8 |

| ZSW380-120 | 600 | 1200*3800 | 90-450 | 15 | 680 | 0 | 6-8 |

| ZSW380-140 | 600 | 1400*3800 | 150-500 | 18.5 | 680 | 0 | 6-8 |

| ZSW380-160 | 600 | 1600*3800 | 200-550 | 22 | 680 | 0 | 6-8 |

| ZSW490-110 | 600 | 1100*4900 | 120-400 | 18.5 | 680 | 0 | 6-8 |

| ZSW490-120 | 600 | 1200*4900 | 150-450 | 18.5 | 680 | 0 | 6-8 |

| ZSW490-130 | 600 | 1300*4900 | 160-480 | 22 | 680 | 0 | 6-8 |

| ZSW490-140 | 600 | 1400*4900 | 180-500 | 30 | 680 | 0 | 6-8 |

| ZSW490-160 | 600 | 1600*4900 | 220-550 | 30 | 680 | 0 | 6-8 |

| ZSW490-180 | 600 | 1800*4900 | 250-650 | 37 | 680 | 0 | 6-8 |

| ZSW490-200 | 600 | 2000*4900 | 500-800 | 37 | 680 | 0 | 6-8 |

| ZSW490-220 | 600 | 2200*4900 | 620-1000 | 37*2 | 680 | 0 | 6-8 |

| ZSW600-140 | 800 | 1400*6000 | 200-550 | 37 | 680 | 5 | 6-8 |

| ZSW600-160 | 800 | 1600*6000 | 230-680 | 37 | 680 | 5 | 6-8 |

language

language