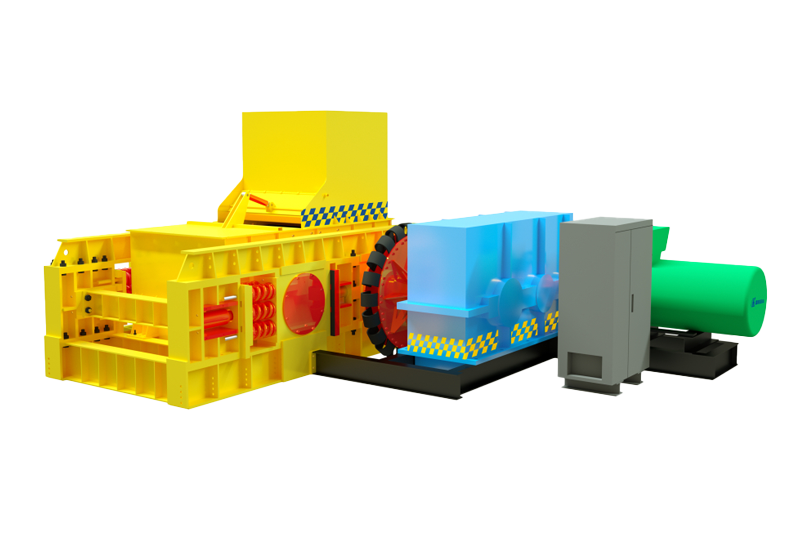

double roller crushing machine

Double roller crusher is mainly used for secondary and fine crushing materials with soft or middle hardness like coal, coke, limestone, clinker mineral, slag, shale and so on. Depending on the requirements, the rolls are smooth or toothed.

Feed Size : ≤100mm

Motor Power : 11-90KW

Capacity : 10-85 t/h

What is roller crusher?

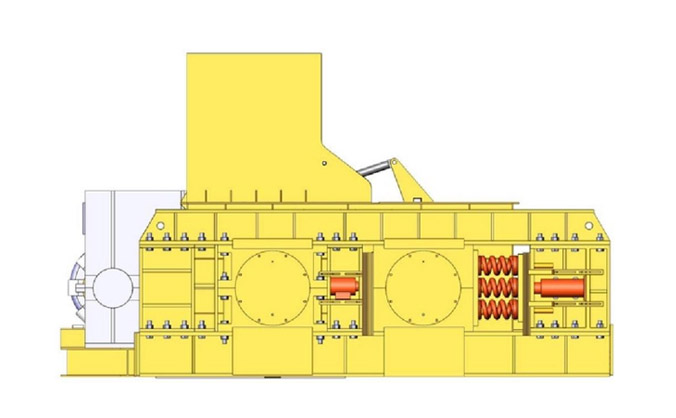

The roller crusher is kind of crushing machine using two opposite rotating rollers to crush material. It is mainly composed of rollers assembly, roller support bearing, pressing and regulating device and driving device. It is suitable for fine crushing process with feed size less than 80mm and finished product size from 50μm-20mm. For example, crushing pebbles and construction waste to make artificial sand, fine crushing iron ore, quartz stone in mining, crushing raw materials in ceramic industry, and in the coal industry, it can be broken directly after removing iron and impurities. It is suitable to crush coarse and brittle bulk materials, with large feeding particle size and adjustable discharging particle size.

Why choose roller crusher?

1.Using domestic advanced wear-resistant materials, it has the advantages of long service life, not easy to damage,and convenient maintenance.

2.Compact structure, small size,convenient operation, low operating cost,stable operation, high efficiency and energy saving,and high crushing rate.

3.The feeding port adopts hydraulic device, when the material enters the roller crusher, the distribution is more even, and the uneven wear of the equipment is avoided.

4.The automatic oil injection system is adopted, and the equipment is more intelligent.

5.High-pressure roller sand making machine has abandoned the shortcomings of low output and high rate of flake strip of traditional roller sand making machine. Its unique kneading and high-pressure

lamination working principle makes the finished product with high output and full particles, which is comparable to the machine-made sand produced by impact sand making machine. It can also be used as a shaping machine.

6.The unique working principle of roller sand making machine has broken through the global difficulty of 5-10mm melon stone sand making, and its sand making rate has reached more than 65% (finished sand below 4mm)

High Quality

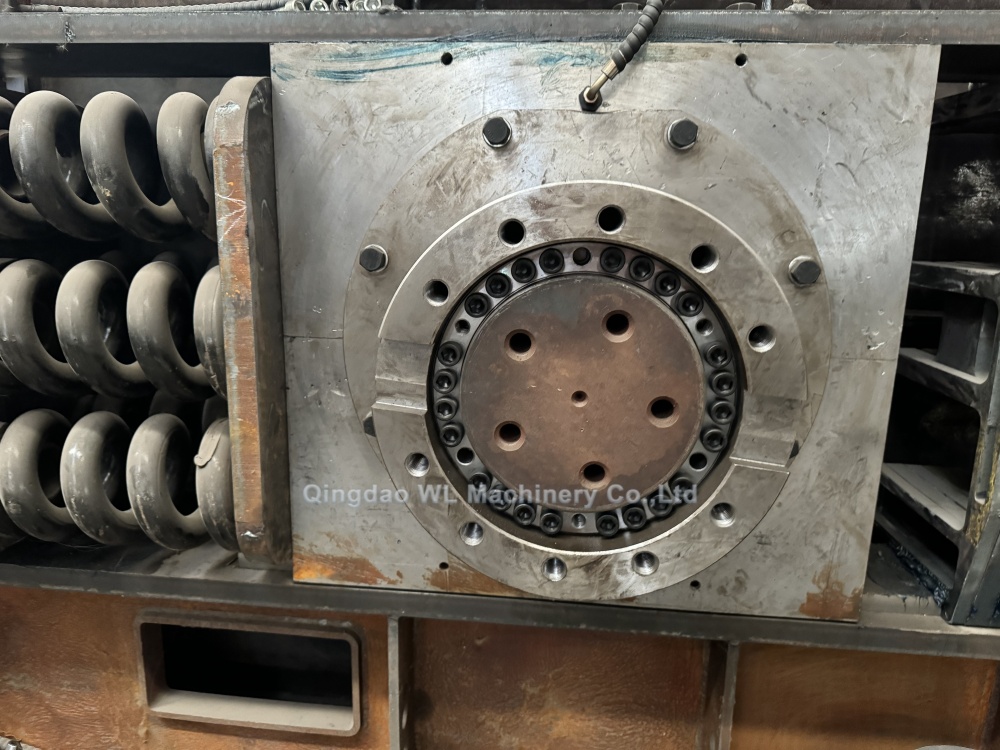

The rollers is wear-resisting chromium molybdenum copper alloy with long service.

Customized Design

This crusher is equipped with motorless scraper. When the raw material has high moisture content,

Good Performance

The gap between the rollers is adjustable, so that the output size and capacity will be changed accordingly.

|

|

|

Working principle

The materials to be crushed fall from the feeding mouth to the space between the two rolls. After being squeezed and crushed, the final products will naturally fall. When there are too hard materials or materials that cannot be crushed, the rolls of the roller crusher will automatically withdraw under the effect of hydraulic cylinder or spring to increase the gap between the rolls, and the too hard materials or the materials that cannot be crushed will fall down. Thus protecting the machine from being damaged. There is a certain gap between the two rolls that rotate at the opposite direction, and the maximum discharging granularity of the final products can be controlled by changing this gap. Double roller crusher's the materials by relying on the two round rollers rotating at the opposite direction, and four-roll crusher crushes the materials by relying on the two pairs of round rollers rotating at the opposite direction.

|

|

| Model |

Roller Diameter (mm) |

Roller Length (mm) |

Feeding Size (mm) |

Capacity (t/h) |

Motor Power (kw) |

| 2PG-400X250 | 400 | 250 | ≤ 25 | 2-10 | 2*5.5 |

| 2PG-610X400 | 610 | 400 | ≤ 30 | 5-20 | 2*15 |

| 2PG-610X750 | 610 | 750 | ≤ 30 | 5-30 | 2*18.5 |

| 2PG-750X500 | 750 | 500 | ≤ 35 | 10-40 | 2*18.5 |

| 2PG-800X600 | 800 | 600 | ≤ 40 | 12-50 | 2*22 |

| 2PG-800X800 | 800 | 800 | ≤ 40 | 20-60 | 2*37 |

| 2PG-900X900 | 900 | 900 | ≤ 50 | 30-70 | 2*37 |

| 2PG-1000X1000 | 1000 | 1000 | ≤50 | 50-100 | 2*45 |

| 2PGY-1200×1000 | 1200 | 1000 | ≤50 | 60-120 | 2*75 |

| 2PGY-1200×1200 | 1200 | 1200 | ≤60 | 80-150 | 2*90 |

| 2PGY-1500×1000 | 1500 | 1000 | ≤80 | 90-200 | 2*132 |

| 2PGY-1800×1000 | 1800 | 1000 | ≤ 100 | 130-250 | 2*220 |

language

language