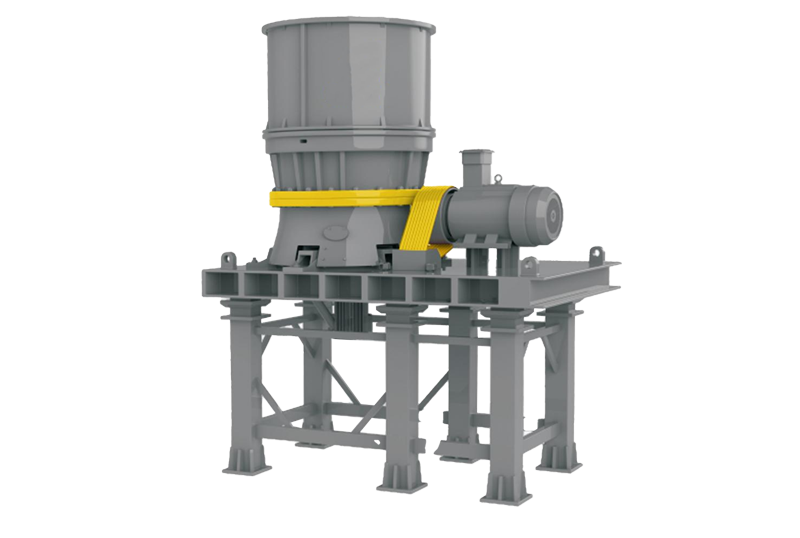

single Cylinder Cone Crusher

Single-cylinder hydraulic cone crusher is new type high efficiency cone crusher machine. It is widely used due to its lightweight, small size, high crushing efficiency, large output, good grain shape and a high degree of automation.

Applicable materials: iron ore, non-ferrous metal ore, granite, limestone, quartzite, sandstone, river pebbles, etc.

Feed size :31-428mm

Power : 90-700KW

Capacity : 27-2193 ton/h

What is single-cylinder hydraulic cone crusher?

THE SINGLE CRLINDER CONE CRUSHER ADOPTS MATERIAL LAYERED SELECTIVE CRUSHING. THE CRUSHING CHAMBER IS FILLED WITH FEED, AND THE MATERIAL IS CRUSHED AND SELF-CRUSHED AFTER BEING SUBJECTED TO ALL-ROUND EXTRUSION, SHEARING AND KNEADINGIN THE CRUSHING CHAMBER, SO THAT THE CRUSHING CHAMBER WALLIS PREVENTED FROM DIRECT CONTACT, EFFECTIVELY PREVENTING THE LINER FROM WEARING EACH OTHER AND PREVENTING THE MATERIAL FROM BEING CONTAMINATED BY METAL POLLUTANTS, THEREBY REDUCING THE WEAR DEGREE OF THE MACHINE'S VULNERABLE AND CONSUMABLE PARTS, EFFECTIVELY EXTENDING THE SERVICE LIFE OF WEAR-RESISTANT PARTS, AND THE CRUSHING RATIO.

GHC/ GHS CONE CRUSHER IS SUITABLE FOR CRUSHING HARD AND MEDIUM HARD ORES , SUCH AS IRON ORE, COPPER ORE , LIMESTONE , QUARTZ , GRANITE , BASALT, DIABASE ...

Why choose single cylinder cone crusher?

1. Wide application range

It can crush relatively hard rocks. The same main machine can obtain multiple cavity types by replacing the liner, so as to adapt to various applications. The medium crushing type has a stable and large feed port, which is used for secondary crushing (even coarse crushing) of materials.

2. Good product particle shape

The optimized combination of crushing frequency, eccentricity. And lamination crushing, so that the crushed material of the discharge port size maintains a good product particle shape.

3. Lower production cost

The optimized liner design makes the unit steel consumption lower; lamination crushing and crowded feeding make the equipment operation rate higher.

4. Simple operation and maintenance

Only button control can be used to achieve stepless adjustment of the discharge port by hydraulic pressure, and it can be carried out during the production process, making the operation more intuitive. After fine processing, wear parts,

5. High degree of automation

GHC/ GHS series cone crusher adopts PLC control system, which can simply operate and control the crusher and reduce labor costs.

Working principle

When the single-cylinder hydraulic cone crusher is working, motor drive the eccentric sleeve by v-belts, transmission shaft and transmission gear. Dynamic conerotary pendulum moved with the action of eccentric sleeve, the moving cone and fixed cone sometimes near sometimes deviation. Material is squeezed in the crushing cavity, impact and breakage, broken material discharge from the bottom.

|

|

| Model |

Power

(KW)

|

Cavity Type | Max feed size (mm) |

Outlet size

(mm)

|

Capacity

(tph)

|

Weight

(kg)

|

Dimensions

(mm)

|

| Standard Cavity Type | |||||||

| GCH420 | 90 | EC/C | 155/103 | 10-32/10-32 | 55-128/59-128 | 5300 | 1300×1500×2160 |

| M/MF | 76/58 | 10-19/8-19 | 57-102/43-75 | ||||

| F/EF | 42/31 | 4-16/4-8 | 27-57/30-40 | ||||

| GCH430 | 160 | EC/C | 215/168 | 13-38/10-38 | 82-212/81-215 | 9200 | 1700×11920×2570 |

| MC/M | 129/101 | 10-32/8-32 | 73-184/61-162 | ||||

| MF/F | 86/62 | 6-25/4-25 | 52-126/42-105 | ||||

| EF | 42 | 4-8 | 70-90 | ||||

| GCH430 | 250 | EC/C | 250/204 | 13-44/13-44 | 112-395/108-378 | 14300 | 2000×2280×2960 |

| MC/M | 157/124 | 13-38/13.39 | 118-328/125-339 | ||||

| MF/F | 98/83 | 13-38/8-32 | 124-299/90-251 | ||||

| EF | 47 | 4-8 | 100-125 | ||||

| GCH660 | 315 | EC/CX | 321/275 | 19-51/19-51 | 190-662/200-654 | 23500 | 2800×3000×3580 |

| C/MC | 253/198 | 16-51/16-51 | 219-643/207-582 | ||||

| M/MF | 155/133 | 16-38/13-38 | 203-539/184-521 | ||||

| F/EF | 96/62 | 13-38/8-25 | 195-423/110-316 | ||||

| GCH870 | 630 | EC/C | 350/287 | 25-70/22-70 | 477-1512/483-1464 | 50000 | 2450×3050×4480 |

| MC/C | 236/184 | 19-70/19-70 | 443-1373/432-1372 | ||||

| EF/F | 108/99 | 16-51/13-44 | 398-1070/357-912 | ||||

| EF | 88 | 10-44 | 290-775 | ||||

| GCH860 | 500 | EC/C | 315/263 | 16-51/16-51 | 326-1071/320-1126 | 50530 | 2101×2583×4047 |

| MC/M | 196/152 | 16-51/16-51 | 314-1055/3289-1036 | ||||

| GCH850 | 500 | MF/F | 123/97 | 10-44/10-44 | 210-700/189-680 | 49750 | 2101×2583×4138 |

| EF | 72 | 10-44 | 168-560 | ||||

| GCH890 | 750 | EC/C | 428/382 | 20-70/22-70 | 594-2181/622-2193 | 97031 | 2900×3360×5300 |

| MC/M | 302/219 | 19-70/16-70 | 542-2020/567-1814 | ||||

| MF/F | 149/139 | 16-70/13-57 | 507-1607/248-1458 | ||||

| GCH895 | 750 | EFX/EF | 112/97 | 13-57/10-70 | 392-1320/305-1210 | 96483 | 2900×3360×5300 |

| EEF | 86 | 10-51 | 306-906 | ||||

| Special Coarse Cavity Type | |||||||

| GCS420 | 90 | EC/C | 240/200 | 22-38/19-32 | 102-168/82-128 | 6800 | 1300×1500×2500 |

| GCS430 | 160 | EC/C | 360/300 | 25-54/25-48 | 151-344/170-330 | 12000 | 1700×1900×3060 |

| MC | 235 | 22-48 | 130-275 | ||||

| GCS440 | 250 | EC/C | 450/400 | 35-54/32-51 | 309-601/331-571 | 19300 | 2000×2280×3620 |

| MC | 300 | 29-51 | 281-505 | ||||

| GCS660 | 315 | EC/C | 160/500 | 38-83/35-70 | 331-792/335-755 | 35000 | 2800×3000×4500 |

language

language