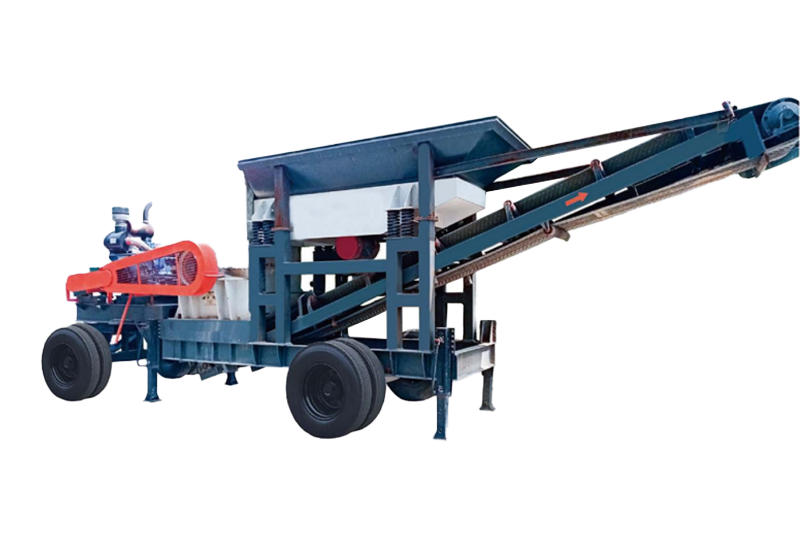

mobile hammer crusher

Mobile hammer crusher is used to crush large stone into gravels and sand due to large crushing ratio. It could crush and screen large reinforced concrete in concrete recycling industry.

Feed size : <800mm

Capacity : 10-500T/h

Power : 50-400kw

Mobile hammer crushing plant is a tire-type mobile crushing station mainly crushed by heavy hammer crushers. Heavy hammer crushers can directly crush materials with a particle size of 600-1200 mm to below 25 mm at one time. The equipment is suitable for crushing various medium-hard and brittle materials such as limestone with a compressive strength not exceeding 150 MPa and a calcium content higher than 40. The mobile heavy hammer crusher has a large crushing ratio and a simple structure. It is assembled on the same frame with the feeder and vibrating screen, and crushing and screening are integrated. The price is relatively cheap and it has a wide range of applications, especially for construction waste.

How to choose mobile heavy hammer crusher plant?

According to material properties. That is the key factor affecting production efficiency and capacity. Therefore, before purchasing the mobile heavy hammer crusher plant, the user must have a detailed understanding of the humidity, hardness, physical and chemical properties of the materials to be crushed.

According to finished granularity requirement. Because each user has different requirements for product particle size, the selection of equipment model will also be affected by it.

Since the prices of each type of mobile stone crusher are different, users must consider their own production conditions when purchasing a mobile crusher, and strive to obtain large returns with a small investment.

Product features :

Highly automatic:Our design make Feeding, crushing and screening machines are all-in-one carbody.

High crushing ratio : Customized Design hammer crusher could crush large size stone into small granules.

Low operation cost: It needs only several workers to work on this plant.

Working principle

The mobile construction waste crushing plant includes vibrating feeder, stone crusher, vibrating screen, belt conveyor, magnetic separator etc. When construction waste is fed to vibrating feeder by the loader, they are crushed by heavy hammer crusher. The crusher materials will go to vibrating screen by foldable belt conveyor. After screen, the unqualified stone will go to crush again, the other qualified aggregates will be piled for further processing, such as removing iron, separating wood chips, cleaning etc.

| Model | MCPC850 | MCPC1011 | MCPC1212 | MCPC1412 | MCPC1414 | MCPC1614 |

| Vibrating Feeder | ZSW0836 | ZSW1036 | ZSW1236 | ZSW1236 | ZSW1436 | ZSW1436 |

| Hammer Crusher | PC850 | PC1011 | PC1212 | PC1312 | PC1412 | PC1614 |

| Feeding Size(mm) | 500 | 600 | 700 | 700 | 700 | 800 |

| Power(kw) | 55 | 75 | 90 | 132 | 75X2 | 90X2 |

| Vibrating Screen | YP1555 | YP1865 | YP2165 | YP2465 | YP2465 | YP2570 |

| Belt Conveyor | B650 | B800 | B800 | B800 | B1000 | B1000 |

| Capacity (t/h) | 10-80 | 60-120 | 80-150 | 100-180 | 100-230 | 120-240 |

| Overall Size(mm) | 8900x1950x5350 | 9900x2150x5650 | 11900x2250x6150 | 11900x2580x6150 | 11900x2580x6150 | 15300x2900x6980 |

language

language