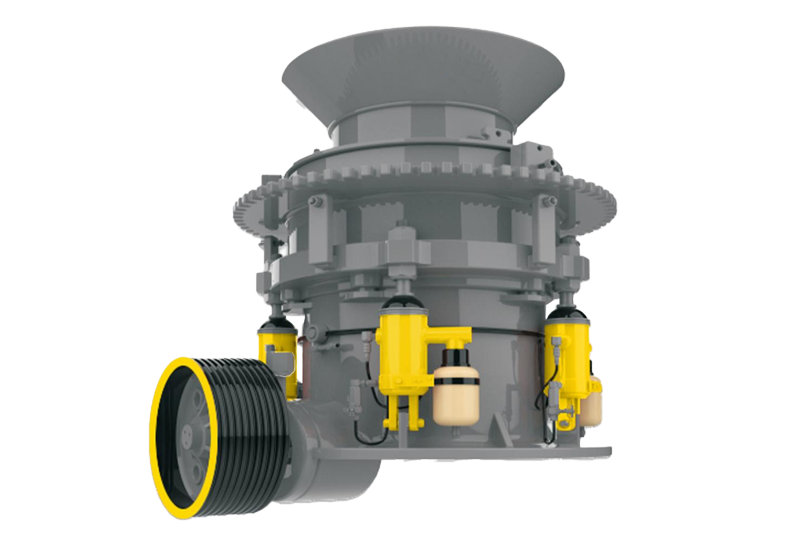

Multi- Cylinder Cone Crusher

Multi-cylinder hydraulic cone crusher are characterized by robust design and high performance with integrated crushing speed, stroke and crushing chamber perfectly. It is ideal stone crusher in aggregates production to meet coarse and fine crushing require

Feed Size ≤240mm

Motor Power 75-375KW

Processing capacity 45-600t/h

What is GHP cone crusher?

Hydraulic cone crusher is a medium and fine crushing machine. It adopts hydraulic system to adjust the discharge opening and is used to protect the cone crusher from overload. The shape design of cone crushing chamber is more scientific, and the hydraulic and lubrication systems are double-safety controlled. GHP cone crusher can be widely used in mines and gravel aggregate industries, suitable for crushing various materials with medium hardness or above. Such as iron ore, non-ferrous metals, granite, limestone, quartz, sandstone, river pebbles and other ores and rocks.

Why choose HP cone crusher?

1. The multi-cylinder hydraulic cone crusher is equipped with a hydraulic motor, which can automatically adjust the mine opening, and automatically remove the fixed cone and the movable cone.

2. If the multi-cylinder hydraulic cone crusher stops under load, the hydraulic cavity cleaning system can quickly clean the crushing cavity, greatly reducing the downtime.

3. The special thin oil lubrication system design of the multi-cylinder hydraulic cone crusher improves the lubrication performance of the equipment and prolongs the service life of the equipment.

4. The special crushing chamber designed by the principle of intergranular lamination and the matching speed can realize selective crushing of materials, and the crushing particle size is uniform.

-

High Quality

Laminated crushing brings good product shape. It improves the quality of finished product and decreases the cost of equipment and whole system.

-

Customized Design

Higher crushing efficiency with optimized crushing chamber. Several standard crushing chambers are available for each model.

-

Good Performance

The cylinder with hydraulic system provides overload and non-broken material protection. It saves the time of maintenance and decreases the operation cost.

|

|

Working principle

Cone crusher is a compression type of stone crusher. The feeding rock is crushed by squeezing or compressing the feed material between a wear resistant mantle and a manganese concave or a bowl liner.

The whole working process of HPC multi-cylinder hydraulic cone crusher is that motor drives the rotation of transmission shaft by belt pulley and v-belts, then transmission shaft drives the rotation of eccentric sleeve around the main shaft through the spiral bevel gear, squeezing or compressing the materials continuously. The material is crushed from all directions, crushed and grinded according to their own grain, which formed the high compressive strength building aggregates. The materials are small enough to fall through the narrow opening at the bottom of the crusher.

Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point

GHP SERIES Multi-cylinder hydraulic cone crusher

| Model |

Power

(KW)

|

Cavity |

Inlet size

(mm)

|

Outlet size

(mm)

|

Capacity

(tph)

|

Weight

(kg)

|

| GHP100 | 90 | EF/F/M/C/EC | 20-150 | 6-32 | 45-140 | 5400 |

| GHP200 | 132 | EF/F/M/C | 25-185 | 10-38 | 90-250 | 10400 |

| GHP300 | 200 | EF/F/M/C/EC | 25-233 | 10-45 | 115-440 | 15810 |

| GHP400 | 315 | EF/F/M/C/EC | 30-299 | 10-51 | 140-630 | 23000 |

| GHP500 | 355 | EF/F/M/C/EC | 35-335 | 10-51 | 175-790 | 33150 |

| GHP800 | 600 | F/M/C/EC | 33-353 | 10-51 | 260-1200 | 64100 |

| GHP3 | 220 | EF/F/M/C/EC | 18-200 | 8-45 | 94-388 | 17600 |

| GHP4 | 315 | EF/F/M/C/EC | 67-237 | 8-45 | 135-555 | 25800 |

| GHP5 | 370 | EF/F/M/C/EC | 50-312 | 8-45 | 158-600 | 28820 |

| GHP6 | 450 | EF/F/M/C/EC | 52-328 | 10-45 | 200-790 | 45400 |

GH SERIES HEAVY DUTY Multi-cylinder hydraulic cone crusher

| Model |

Power (kw) |

Cavity Type |

Inlet size (mm) |

Closed Edge Discharge Port Size (mm) | ||||||||||

| Capacity (t/h) | ||||||||||||||

| 13 | 19 | 25 | 31 | 38 | 44 | 51 | 64 | 70 | 76 | 84 | ||||

| H300 | 75/90 | EF | 45 | 55-60 | 75-100 | 80-90 | ||||||||

| F | 70 | 55-65 | 75-90 | 80-110 | ||||||||||

| M | 90 | 60-70 | 80-100 | 95-120 | ||||||||||

| C | 150 | 60-70 | 80-110 | 100-130 | 130-180 | |||||||||

| EC | 180 | 85-110 | 120-140 | 130-200 | 140-220 | |||||||||

| H400 | 180/220 | EF | 50 | 115-130 | 130-150 | 160-200 | ||||||||

| F | 70 | 120-135 | 135-165 | 165-225 | 195-230 | |||||||||

| M | 100 | 130-170 | 150-180 | 180-210 | 220-280 | 260-320 | ||||||||

| C | 150 | 180-220 | 220-300 | 250-300 | 280-360 | 350-420 | 400-500 | |||||||

| EC | 240 | 220-300 | 240-320 | 260-330 | 300-420 | 360-430 | 410-530 | |||||||

| H500 | 280/315 | EF | 60 | 180-300 | 300-340 | 320-430 | 360-460 | |||||||

| F | 100 | 310-350 | 350-420 | 360-440 | 380-480 | |||||||||

| M | 150 | 320-360 | 305-420 | 370-440 | 390-500 | |||||||||

| C | 250 | 365-430 | 375-385 | 400-520 | 430-550 | 500-620 | 560-780 | |||||||

| EC | 330 | 370-440 | 380-500 | 450-550 | 480-580 | 520-660 | 580-800 | |||||||

| H600 | 355/400 | EF | 90 | 290-370 | 380-430 | 400-590 | ||||||||

| F | 125 | 390-470 | 400-620 | 490-690 | 520-760 | |||||||||

| M | 230 | 400-630 | 480-700 | 550-800 | ||||||||||

| C | 300 | 495-710 | 550-800 | 600-850 | 650-880 | |||||||||

| EC | 370 | 600-850 | 680-900 | 780-950 | ||||||||||

| H700 | 450/500 | EF | 95 | 340-450 | 420-480 | 490-660 | ||||||||

| F | 130 | 420-500 | 510-640 | 540-750 | 560-820 | |||||||||

| M | 250 | 530-680 | 560-750 | 570-830 | 630-880 | |||||||||

| C | 330 | 560-760 | 570-845 | 650-900 | 690-910 | |||||||||

| EC | 400 | 575-850 | 670-950 | 720-1000 | 800-1150 | 930-1250 | 950-1310 | |||||||

| H880 | 560/630 | EF | 100 | 380-730 | 490-780 | 540-860 | ||||||||

| F | 150 | 490-500 | 550-840 | 590-900 | 650-1020 | |||||||||

| M | 250 | 560-880 | 620-950 | 670-1030 | 730-1280 | |||||||||

| C | 330 | 610-940 | 670-1045 | 750-1200 | 890-1310 | |||||||||

| EC | 400 | 675-1050 | 770-1250 | 810-1300 | 1050-1350 | 1120-1350 | 1200-1590 | |||||||

| H900 | 630/710 | EF | 100 | 400-860 | 490-800 | 600-920 | ||||||||

| F | 150 | 480-830 | 610-940 | 640-1250 | 760-1590 | |||||||||

| M | 250 | 630-980 | 660-1300 | 770-1590 | 790-1650 | 830-1880 | ||||||||

| C | 370 | 660-1310 | 780-1600 | 800-1620 | 890-1800 | 950-2150 | 1050-2160 | 1210-2550 | 1480-2600 | |||||

| EC | 420 | 790-1600 | 880-1800 | 930-2150 | 930-1250 | 1250-2550 | 1500-2600 | |||||||

| H1100 | 800 | EF | 100 | 490-990 | 595-1170 | 700-1320 | ||||||||

| F | 150 | 585-1130 | 700-1360 | 790-1775 | 810-1850 | |||||||||

| M | 250 | 710-1330 | 800-1710 | 860-1830 | 910-1915 | 1130-2450 | ||||||||

| C | 370 | 820-1725 | 840-1860 | 930-1940 | 1190-2430 | 1270-2550 | 1470-2620 | 1590-2770 | 1650-2800 | |||||

| EC | 420 | 917-1920 | 1180-2420 | 1230-2595 | 1410-2630 | 1550-2750 | 1630-2800 | |||||||

| H1300 | 1000 | EF | 110 | 570-1370 | 640-1390 | 810-1510 | ||||||||

| F | 150 | 655-1420 | 820-1660 | 890-1800 | 910-1950 | |||||||||

| M | 250 | 810-1690 | 900-1925 | 960-1950 | 1151-2196 | 1230-2650 | ||||||||

| C | 370 | 920-1870 | 990-2000 | 1111-2133 | 1290-2630 | 1390-2752 | 690-2850 | 1790-3030 | 2010-3300 | |||||

| EC | 420 | 1129-2190 | 1280-2620 | 1430-2797 | 1710-2870 | 1830-3050 | 2035-3300 | |||||||

| H1700 | 1250 | EF | 110 | 800-1710 | 950-1750 | 1200-1850 | ||||||||

| F | 160 | 960-1650 | 1200-1850 | 1280-2490 | 1520-3150 | |||||||||

| M | 260 | 1250-1960 | 1300-2580 | 1530-3170 | 1580-3300 | 1650-3760 | ||||||||

| C | 380 | 1310-2630 | 1650-3190 | 1600-3240 | 1720-3810 | 1900-4300 | 2010-4320 | 2410-5090 | 2950-5200 | |||||

| EC | 430 | 1590-3300 | 1700-3790 | 1950-4330 | 1850-4310 | 2450-5170 | 2990-5220 | |||||||

language

language