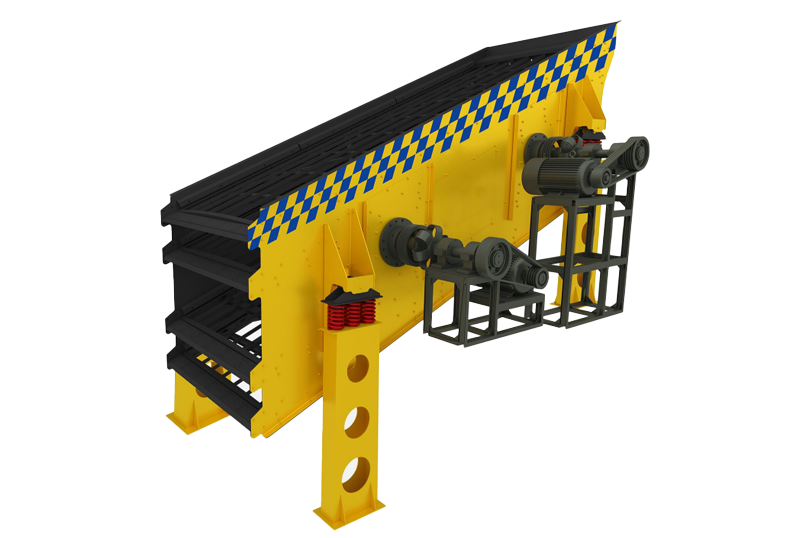

YP vibration Screen

YP Series circular vibrating screen can be used to separate minerals into various sizes for further processing in stone crushing plant. QDWL company can design and supply all ranges of vibrating screens according to the capacity and requirement.

Feed size : 0- 150mm

Power : 4-90kw

Capacity : 10-450t/h

What is YP series vibrating screen?

YP series circular vibrating screen is called circular vibrating screen for short because its motion track is similar to a circle. It uses the inner eccentric shaft as excitation force to make screen machine a circular motion track of up, front, down and back, so that the screened materials can evenly slide through the screen to complete screening work. It could be made into one deck, two decks, three decks and four decks to get different size material. The vibrating screen is used for screening sand and gravel in quarries, and can also be used for product classification in coal preparation, mineral processing, building materials, electric power and chemical industries.

|

|

|

How to choose vibrating screen?

1. When selecting a vibrating screen, the shape, moisture, clay content, etc. of the screened material should be considered. Appropriate materials can improve the production efficiency of the vibrating screen.

2. Consider the screen area, movement mode, vibration frequency and other factors of the vibrating screen. For example, when the moving sieve sieves particles, the particles can vibrate on the sieve surface in a direction close to the vertical sieve hole. The vibration frequency is high and the sieving effect is better.

3. The vibrating screen capacity should be compatible with related equipment. If the production capacity is too rich, capital investment will be wasted. Overload operation will cause wear and tear and reduce production capacity.

4. According to different screening purposes, it needs to choose different vibrating screen type, such as pre-screening material can choose circular vibrating screen; The classification and screening of materials after crushing can use large vibrating screen; Linear vibrating screen can be used to dehydrate the material.

4.The structure of small amplitude, high frequency and large angle of inclination makes this machine high in screening efficiency, large processing capacity, long life, low power consumption and low noise.

| Model |

Max feed size

(mm)

|

Layers | Capacity (t/h) | Power(kw) | Screen size ( mm ) |

Frequency

(r/min)

|

Double Amplitude

(mm)

|

Installation angle | Dimension (L*W*H)(mm) |

| YP0924 | 60 | 2-3 | 10-40 | 4KW-6 | 2250*870 | 960 | 6-8 | 20° | 2837*1424*1200 |

| YP1230 | 70 | 2-4 | 25-60 | 7.5KW-6 | 1160*1550 | 960 | 6-8 | 20° | 3557*1724*1530 |

| YP1236 | 70 | 2-3 | 30-65 | 7.5KW-6 | 1850*1160 | 960 | 6-8 | 20° | 4146*1724*1500 |

| YP1345 | 80 | 2-4 | 40-80 | 15KW-6 | 1300*4000 | 960 | 6-7 | 20° | 5240*2000*2150 |

| YP1555 | 90 | 2-4 | 50-100 | 22KW-6 | 1500*5000 | 960 | 6-8 | 20° | 6340*2340*2350 |

| YP1865 | 80 | 2-4 | 70-150 | 22KW-6 | 1800*6000 | 960 | 6-8 | 20° | 7385*2620*2430 |

| YP2165 | 120 | 2-4 | 100-240 | 30KW-6 | 2100*6000 | 960 | 6-8 | 20° | 7385*2920*2430 |

| YP2465 | 120 | 2-4 | 120-260 | 37KW-6 | 2400*6000 | 960 | 6-8 | 20° | 7202*3220*1950 |

| YPS2570 | 120 | 2-4 | 150-300 | 30KW-6*2 | 2500*6500 | 960 | 6-9 | 22° | 7890*3360*2450 |

| YPS3070 | 120 | 2-3 | 200-400 | 37KW-6*2 | 3000*6500 | 960 | 6-9 | 22° | 7730*3860*2000 |

| YPS3585 | 150 | 2-3 | 280-450 | 45KW-6*2 | 3500*8000 | 960 | 6-9 | 25° | 9320*4440*2245 |

| XP2165 | 120 | 2-4 | 100-240 | 30KW-6 | 2100*6000 | 960 | 6-8 | 22° | 7630*3030*2360 |

| XPS2572 | 150 | 2-4 | 150-320 | 30KW-6*2 | 2500*6700 | 960 | 6-9 | 22° | 8400*3400*2360 |

| XPS3080 | 150 | 2-3 | 220-420 | 37KW-6*2 | 3000*7500 | 960 | 6-9 | 22° | 9300*3900*2050 |

language

language