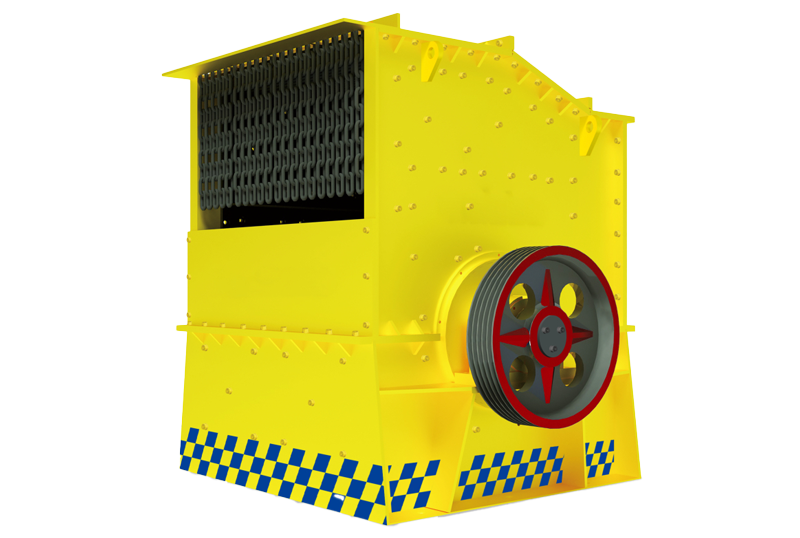

hammer crusher

【Feeding Size】: ≤ 1000mm

【Output Size】: 15 – 300mm

【Capacity】: 50 – 800T/H

【Crushing materials】: Quartz, granite, basalt, limestone, river stone, sandstone, shale, iron ore, copper ore, gold ore etc.

【Applications】: Widely used in various industries, such as mining, road and railway construction, building construction,water conservation and chemical industry etc.

If you are a beginner and do not know about jaw crusher machines, tell us your raw material characteristics, finished product requirements, site conditions, production budget, hourly production, and other requirements, we have professional engineers to equip you with a suitable model at a reasonable price. Next, let’s see the types of jaw crusher we can supply. Learn more about each jaw crusher specification and application.

Type of Jaw Crusher for Sale

It is suitable for crushing various medium-hard and brittle materials with compressive strength of the crushed material does not exceed 350 MPa, such as limestone, coal, salt, gypsum, alum, brick, tile, coal gangue, etc.

|

|

THE Advantages of our Hammer Crusher :

1. With large crushing ration, heavy hammer crusher feeding granularity is large and discharge granularity is small. It could reduce the crushing stage and can save some equipment investment.

2. The heavy hammer crusher integrates coarse crushing and shaping functions when crushing stone. It does not need to go through the secondary crushing and shaping process.

3. With triple crushing force, the hammer head hits the material, the material hits the impact plate at high speed, and the stone rebounded by the impact plate hits the material hit by the hammer head. So PC hammer crusher can be more productive and energy-saving.

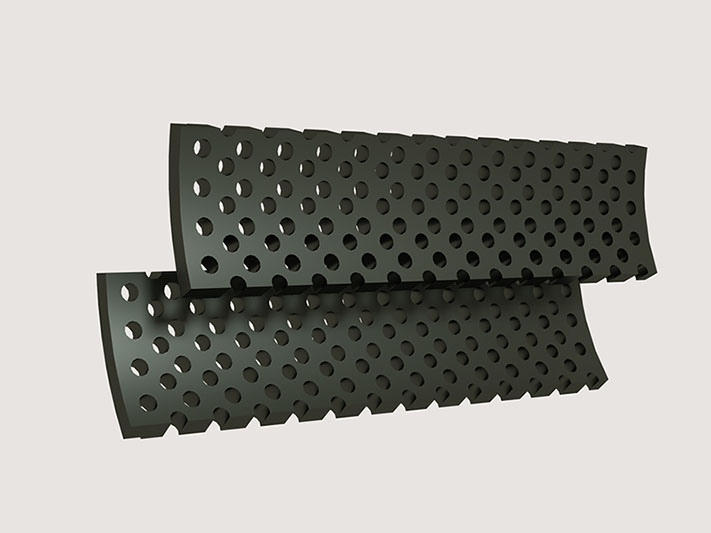

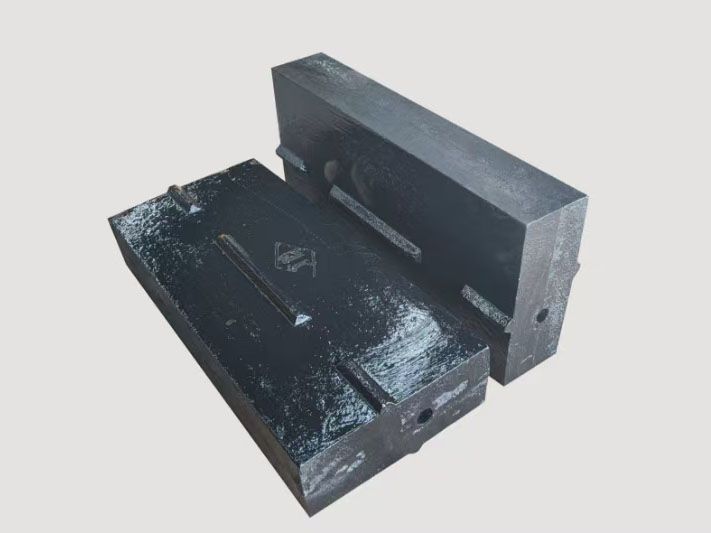

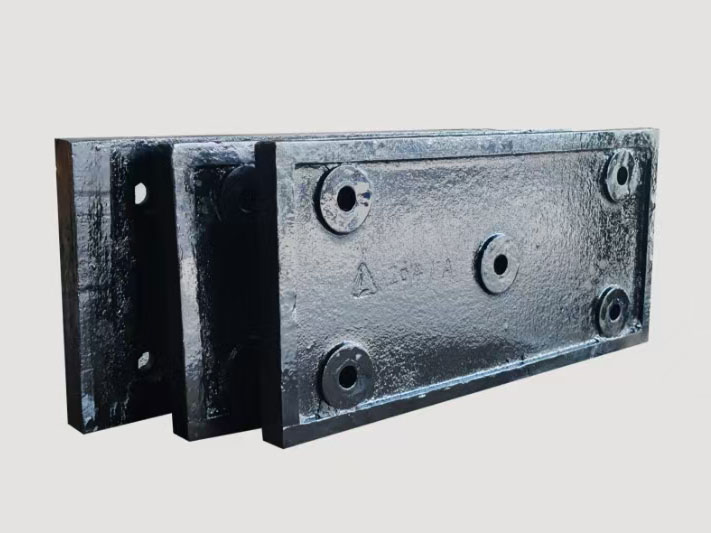

4. The heavy hammer crusher adopts a large blow bar to replace the hammer head of the original light hammer crusher. After optimized design, the kinetic energy is greater and the service life is longer.

Our company has designed and manufactured hammer crushers for more than 20 years. The product structure is advanced, the performance is reliable, the work is stable, and the energy consumption is low. In addition, the price of the hammer crusher produced by our company is reasonable, and a series of products have been formed, which are welcomed by users at home and abroad.

|

|

|

|

|

|

The hammer crusher is one of the most common limestone stone crushers. There are many models of PC type hammer crusher, among which the most popular models are PC400x600, PC600x800 and high capacity model like PC1413...

| Model | Hammerhead quantity | Input size(mm) | Output Size(mm) | Capacity(t/h) | Power(kw) |

| HC400×300 | 16 | <100 | <15 | 5-10 | 11 |

| HC350×500 | 20 | <100 | <15 | 8-15 | 18.5 |

| HC600×400 | 20 | <220 | <15 | 10-25 | 22 |

| Model | Inlet door size(mm) | Max feed size (mm) | Discharge size(mm) | Running speed(r/min) | Power(kw) | Capacity (t/h) | Dimension(mm) |

| PC850 | 850x650 | 500 | ≤ | 585 | 55-4P | 10-80 | 1450*1780*1685 |

| PC1011 | 1020*660 | 600 | ≤100 | 585 | 75KW-4P | 60-120 | 1600*1960*1870 |

| PC1211 | 1220*750 | 700 | <100 | 520 | 90KW-4P | 80-150 | 1800*2130*2020 |

| PC1212 | 1220*840 | 700 | <100 | 520 | 90KW-4P | 80-150 | 1896*2130*2020 |

| PC1312 | 1320*845 | 700 | ≤100 | 520 | 110KW-4P | 100-180 | 1896*2230*2190 |

| PC1412 | 1420*845 | 700 | ≤100 | 520 | 132KW-4P | 100-180 | 1900*2330*2190 |

| PC1612 | 1620*845 | 320 | ≤100 | 650 | 90KW-4P*2pcs | 120-240 | 1900*2530*2190 |

| PC1413 | 1420*1040 | 800 | ≤100 | 500 | 75KW-4P*2pcs | 100-220 | 2200*2450*2490 |

| PC1414 | 1420*1050 | 800 | <100 | 500 | 75KW-4P*2pcs | 100-230 | 2200*2450*2675 |

| PC1614 | 1620*1050 | 800 | ≤100 | 500 | 90KW-4P*2pcs | 120-240 | 2220*2650*2675 |

| PC1814 | 1820*1050 | 800 | ≤100 | 500 | 110KW-4P*2pcs | 150-320 | 2220*2850*2675 |

| PC2014 | 2020*1050 | 800 | ≤100 | 500 | 160KW-4P*2pcs | 150-400 | 2290*2982*2675 |

| PCH1616 | 1620*1150 | 800 | ≤120 | 550 | 132KW-4P*2pcs | 150-350 | 2480*2855*2955 |

| PCH1816 | 1820*1150 | 800 | ≤120 | 550 | 160KW-4P*2pcs | 180-400 | 2480*3055*2955 |

| PCH2016 | 2020*1150 | 800 | ≤120 | 550 | 220KW-4P*2pcs | 220-500 | 2480*3255*2955 |

| PCH2218 | 2220*1100 | 800 | ≤140 | 550 | 250KW-4P*2pcs | 250-600 | 2710*3580*3100 |

| PCH2620 | 2620*1350 | 800 | ≤200 | 450 | 315KW-4P*2pcs | 550-780 | 3310*4580*3900 |

| PCH2630 | 3030*1400 | 1200 | ≤200 | 390 | 900KW-6P*2pcs | 1800-2500 | 4800*5370*5460 |

In order to overcome the impact of the environment on the work, we can also install crushers, feeders, conveyor belts and other equipment on the axle to make a mobile crushing production line, which not only solves the problem for customers but also improves the efficiency of their production lines.

language

language