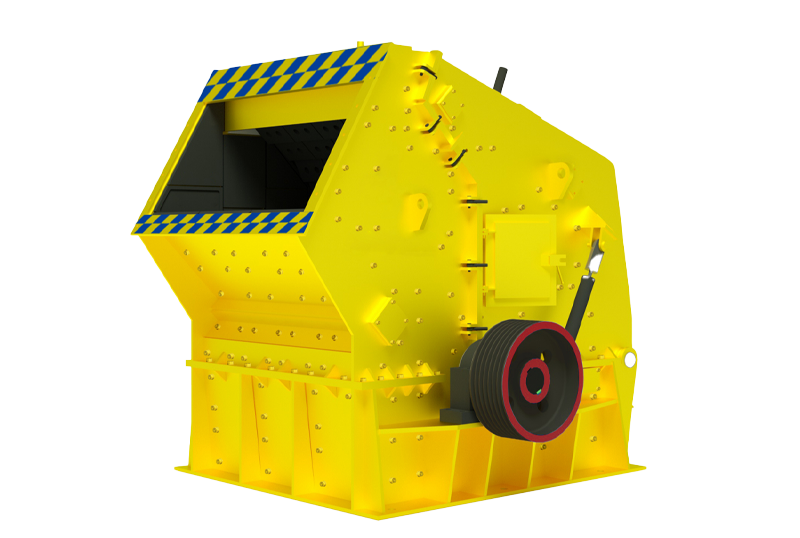

Impact crusher

Impact crusher is utilized in aggregates production, mining operations, and concrete recycling applications. It can be used in all different stages of stone size reduction from primary crushing to the last step of the crushing process.

Feed Size : <360mm

Motor Power :75-500kw

Capacity :30-550 t/h

Strong various coarse,medium and fine materials ( granite, limestone, concrete, etc. ) not exceeding 350MPa.PF series impact crusher can be widely used in various ore crushing, railway, highway, energy, cement, chemical, construction and other industries.

The discharging granularity can be adjusted and the crushing specifications.

Why Choose PF impact crusher?

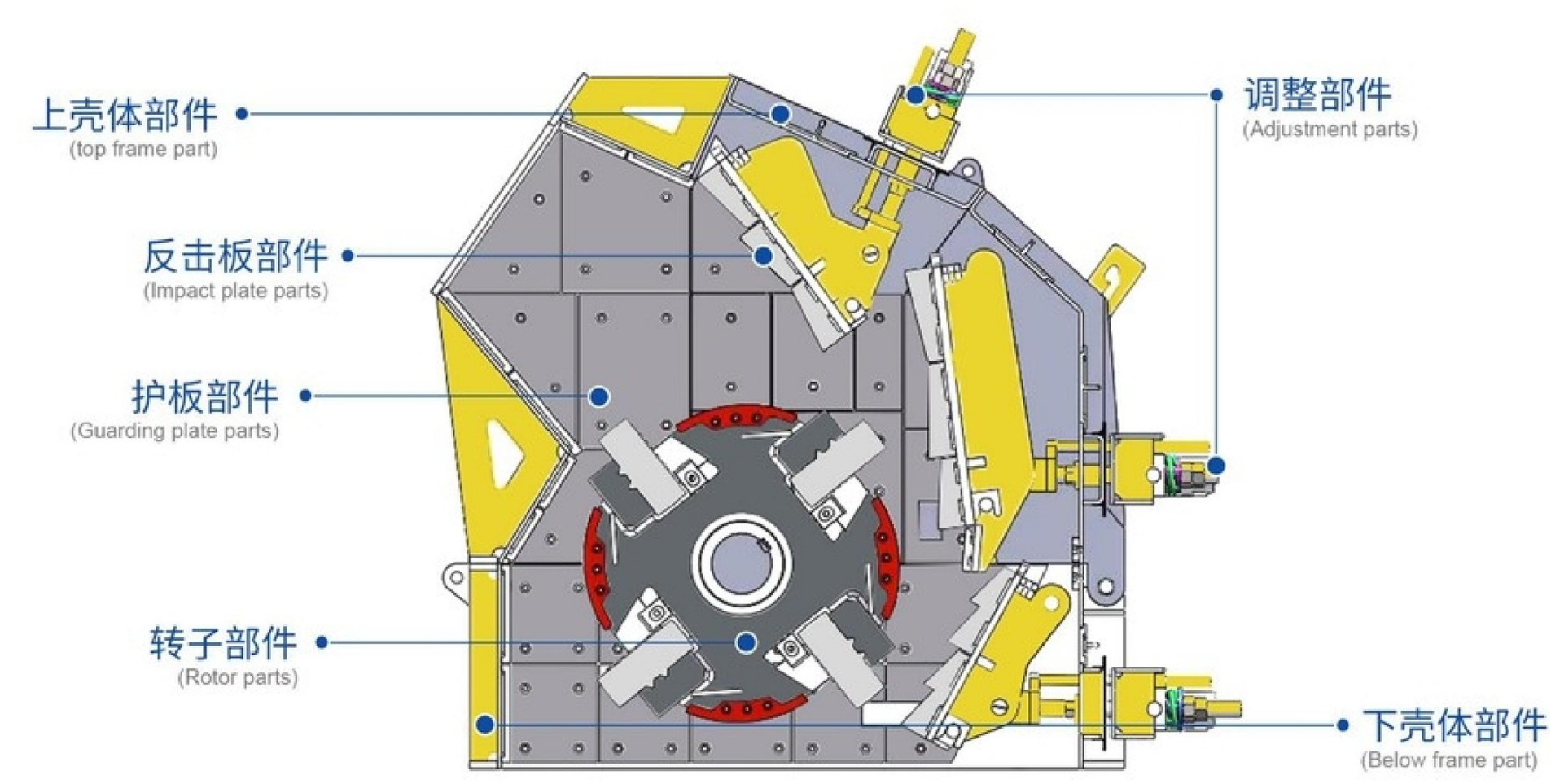

1. Impact crusher is more effective in processing materials with a large amount of moisture. It can effectively prevent material clogging. The impact crusher does not need to be equipped with a bottom sieve plate to effectively prevent clogging.2. Impact crusher is suitable for a wider range of material hardness. The blow bar of the impact crusher is firmly fixed on the rotor with a mechanical clamping structure. When it rotates with the rotor, it has greater momentum, which is suitable for crushing harder materials, and at the same time consumes less energy.

3. It is convenient and flexible to adjust the discharge granularity. The impact crusher can adjust the output particle size in various ways, such as adjusting the rotor speed, adjusting the gap between the impact plate and the grinding chamber, etc. Gap adjustment can be adjusted mechanically or hydraulically.

4. The triple impact plate structure is adopted to increase the number of strikes on the material, hard extrusion, reduce friction, reduce hammer head loss, and prolong the service life of wear-resistant parts.

|

|

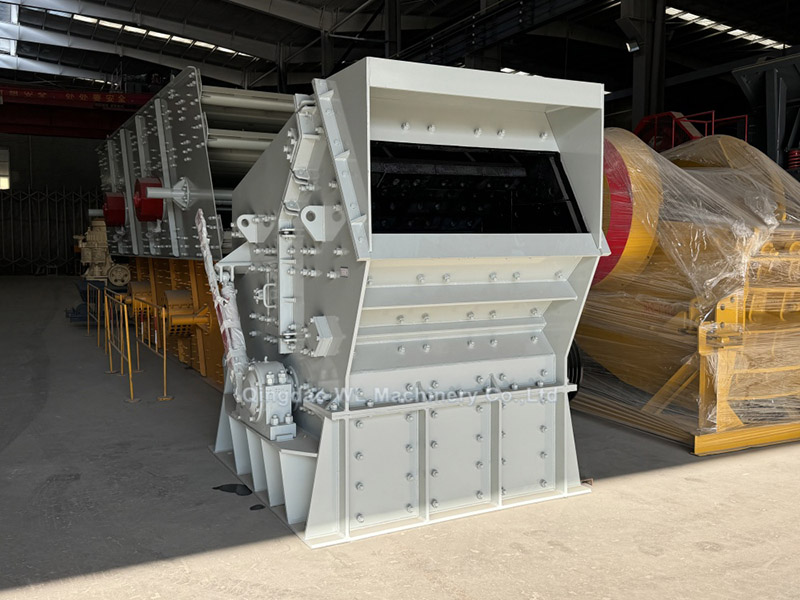

Working principle

Impact crusher is a kind of stone crusher using impact force.

When impact crushing machine works, the motor drives the rotor rotate at a high speed. When the material gets into the blow bar working area, they will be stroke by the blow bar and thrown to the impact devices around the rotor. The material will come out from the discharge hole until they are crushed to the required size.

The materials from large to small all to be crushed at the impact chamber repeatedly. The clearance between the impact rack and the rotor can adjust the size and shape of the end product.

PERFORMANCE CHARACTERISTICS

1.With large feed inlet and high crushing cavity,it is suitable for crushing materials with high hardness and large particle size.

6.Complete crushing function, high production efficiency, high wear resistance of machine parts,low energy consumption and high overall efficiency.

|

|

|

|

|

|

| Model |

Max feeding size

(mm)

|

Adjust range

(mm)

|

Discharge size

(mm)

|

Capacity

(t/h)

|

Power

(kw)

|

Dimension (L*W*H)

(mm)

|

Inlet size

(mm)

|

Rollar speed

(r/min)

|

| PF1010 | 150 | 0-60 | ≤60 | 30-80 | 75KW-6 | 1975*1890*1645 | 1100*410 | 500 |

| PF1210 | 180 | 0-60 | ≤80 | 50-130 | 110KW-6 | 3300*2040*2650 | 1100*600 | 500 |

| PF1214 | 180 | 0-60 | ≤80 | 80-150 | 132KW-6 | 3300*2440*2650 | 1500*600 | 500 |

| PF1315 | 220 | 0-60 | ≤90 | 100-260 | 160KW-6 | 3470*2470*2900 | 1600*650 | 480 |

| PF1518 | 300 | 0-60 | ≤90 | 150-350 | 250KW-6 | 3837*2872*3140 | 1870*995 | 450 |

| PF1620 | 360 | 0-110 | ≤100 | 220-550 | 250KW-4*2台 | 3340*3570*3176 | 2020*828 | 500 |

language

language