concrete pump

As the core equipment for modern building construction, Qingdao WL brand concrete pumps combine intelligent technology and excellent performance, designed for complex engineering scenarios, and dedicated to providing customers around the world with efficient and reliable concrete delivery solutions.

Wide range of applications

Covering commercial concrete mixing plant, municipal construction, water conservancy and hydropower projects, rail transportation and other scenarios, it is the ideal choice for large-scale infrastructure and fine construction.

Service Commitment

We provide 24-hour technical response, customized configuration solutions and global warranty services, escorting your project progress from equipment delivery to construction support.

Choose Qingdao WL concrete pumps to break through construction limits with the power of technology and inject solid power into every landmark!

QDWL concrete pump machine according to the power, it can be divided into electric drag pump and diesel drag pump.

According to the pumping capacity, it can be divided into 30 pumps, 40 pumps, 60 pumps, 80 pumps, 90 pumps, etc. As the name suggests, it pumps 30-90 cubic meters per hour. Among them, the small mini drag pumps 30 pumps and 40 pumps are more suitable for small and medium-sized projects such as rural housing construction.

According to the diameter of pumped aggregate, it can be divided into fine stone pump and large aggregate pump. The fine stone pump can pump the maximum particle size of aggregate ≤30mm. The large aggregate pump can pump the maximum aggregate particle size ≤ 40mm.

|

|

|

|

|

* If you are not sure which type or kind of concrete trailer pump you need, feel free to contact us and our project managers will recommend based on your project requirement.

Performance Characteristics

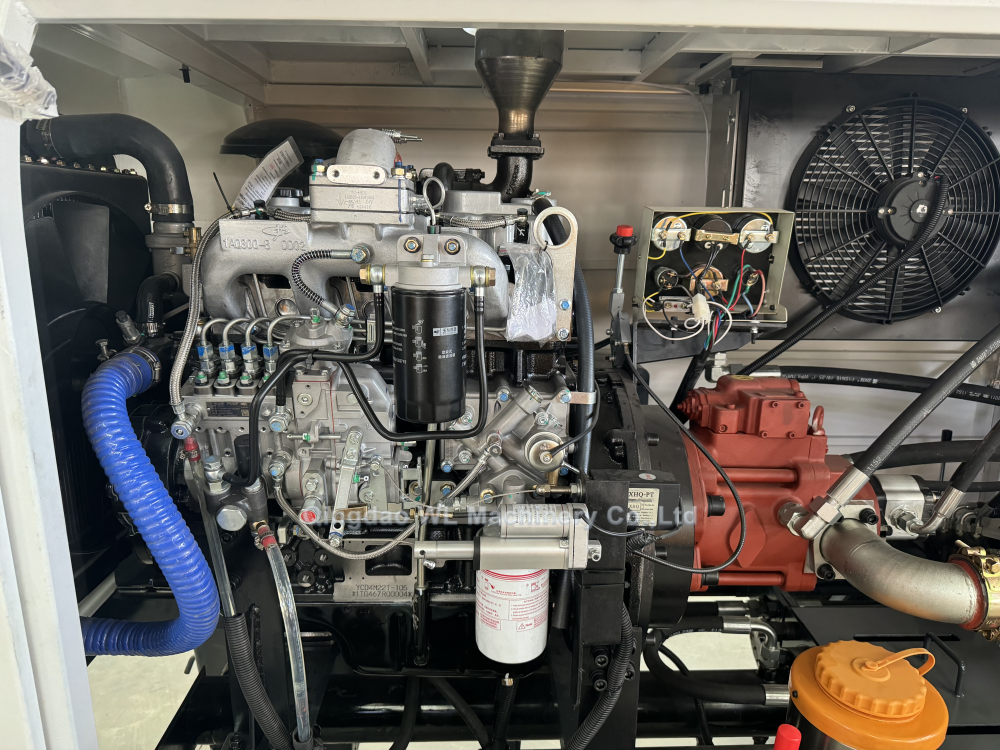

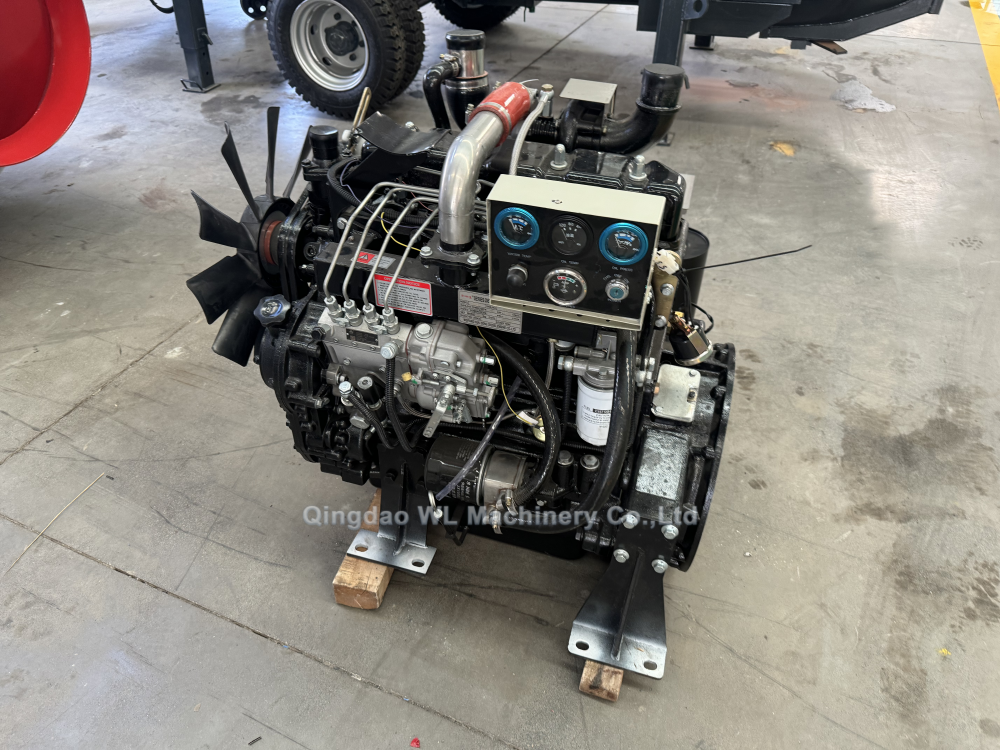

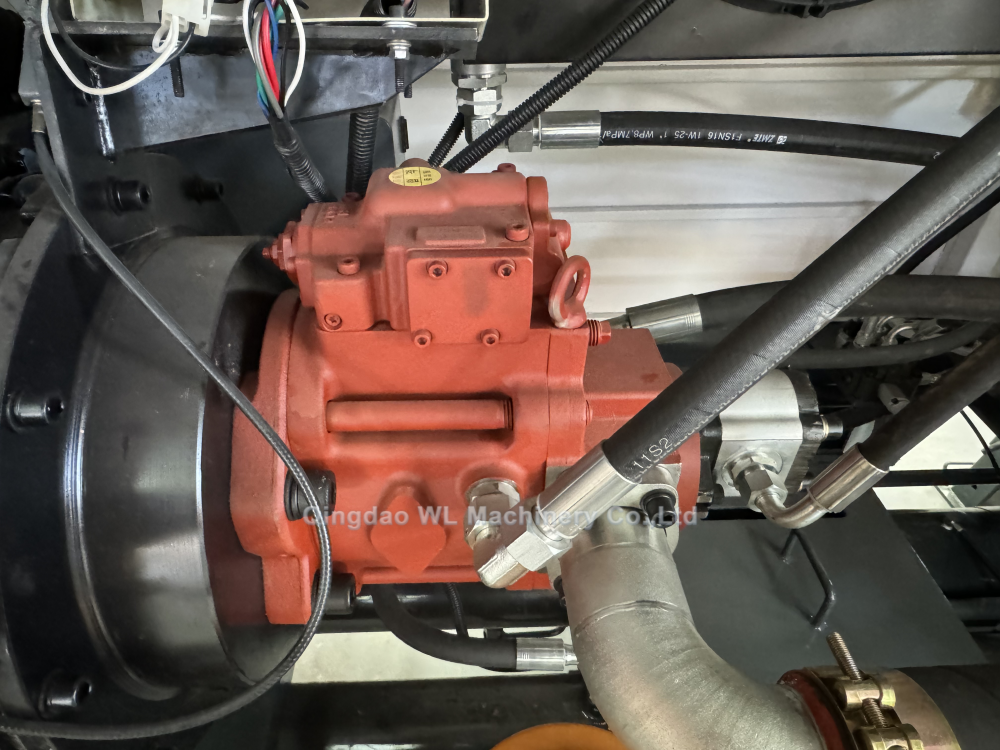

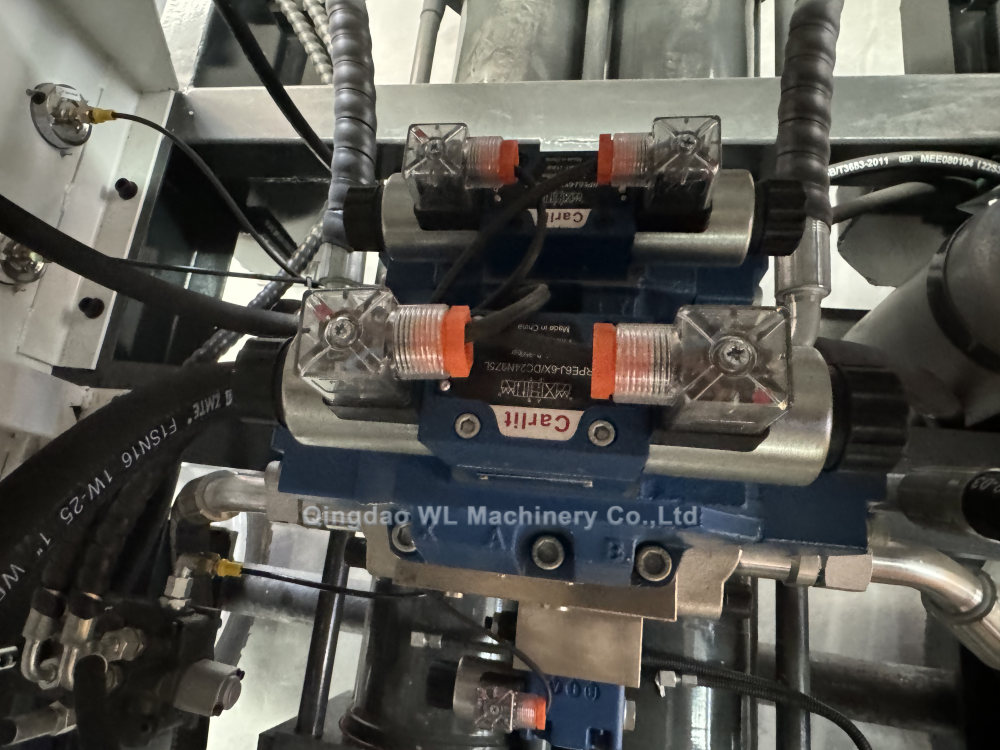

Based on the mature manufacturing technology of electronically controlled reversing concrete pump, our company has successfully developed the fully hydraulic control concrete pump with excellent performance after years of unremitting efforts. The hydraulic system abandons the key components such as PLC, constant pressure pump, accumulator, proximity switch and other key components which are easily damaged in the electronically controlled commutative concrete transfer pump, which significantly improves the reliability of the equipment as a whole and effectively reduces the maintenance cost in the later stage to ensure the equipment to run stably in the harsh environment. Mainly produces all kinds of motor (diesel engine) concrete pumps with conveying capacity of 30-120m³/h and concrete conveying pressure of 5-20Mpa.

-

Cooling System: Utilizes a plate-fin air-cooled radiator to guarantee stable operation at maximum allowable temperatures.

-

Main Hydraulic Pump: Features premium brands like HAWE (Germany), Rexroth, or Kawasaki (Japan).

-

Lubrication System: Employs fully automatic multi-point lubrication technology for targeted lubrication, improving effectiveness and extending the lifespan of wear-prone components.

-

Power System:

-

1. Electric Motor Series: Renowned domestic and international brands, including Yantai Electric Motor, Qingdao Electric Motor, and Siemens Bide.

-

2. Diesel Engine Series: Original Volvo and Lovol engines, and we can also help the customer equip with Weichai brand famous engine too.

-

-

Electrical Components: Primarily uses Schneider and LG products to enhance control system reliability.

-

Hydraulic Hose Fittings: Eaton (USA) products ensure leak-free safety.

-

Cylinder Seals: Parker (USA) seals for large oil cylinders.

-

S-Tube Valve: Crafted from integrally cast high-manganese steel with wear-resistant material welded on high-abrasion surfaces, offering both high-pressure resistance and durability.

-

Wear Plate & Cutting Ring: Manufactured with hard alloy inserts for exceptional longevity.

-

Piston: Precision-machined from imported materials, resistant to hydrolysis, abrasion, and high temperatures.

|

|

|

|

|

|

Features & Advantages of Fully Hydraulically Controlled Systems:

-

Hydraulic-Only Directional Control: Alternating actions of pumping and S-tube distribution require no electrical signals, minimizing switching impact, reducing noise, and extending the lifespan of hydraulic pumps and valves.

-

Enhanced Reliability: Eliminates intermediate electrical signal processes, significantly boosting overall operational reliability.

-

Compact Design: Centralized valve block integrates main hydraulic valves, reducing cross-connected pipelines for a leak-resistant, space-efficient system.

-

Lower Maintenance Costs: Removes four vulnerable components typical of electrically controlled systems, cutting long-term upkeep expenses.

Technical Parameters of Diesel power concrete Pump

| Items | Unit | DHBT | DHBT | DHBT | DHBT | DHBT | DHBT | DHBT |

| 30-10-56 | 40-13-76 | 50-11-76 | 60-13-129 | 80-16-199 | 90-16-199 | 90-22-199 | ||

| Theoretical Capacity | cbm/h | 30 | 40 | 50 | 60 | 80 | 90 | 90 |

| Delivery Pressure | Mpa | 10 | 13 | 11 | H12.5 / L 7.5 | 16 | 16 | 22 |

| Max. Pump Times | times/min | 24 | 24 | 24 | 21 | 23 | 23 | 23 |

| Delivery Height | m | 120 | 120 | 120 | 180 | 180 | 200 | 350 |

| Delivery Distance | m | 500 | 500 | 500 | 600 | 1000 | 800 | 1500 |

| Distribution Valve Type | / | S pipe valve | S pipe valve | S pipe valve | S pipe valve | S pipe valve | S pipe valve | S pipe valve |

| Concrete cylinder diameter x strokes | mm | 160x1000 | 160x1000 | 180x1000 | 200x1600 | 200x2012 | 160x1000 | 160x1000 |

| Oil cylinder specifications | mm | 100x1000 | 100x1000 | 100x1000 | 126x1600 | 90/140 x1800 | 160x1000 | 160x1000 |

| Outlet diameter | mm | 125 | 125 | 180 | 180 | 180 | 180 | 200 |

| Uploading height | mm | 1100 | 1100 | 1100 | 1100 | 1400 | 1400 | 1400 |

| Engine power | kw | 56 | 76 | 76 | 129 | 199 | 199 | 199 |

| Rotated speed | r/m | 2200 | 2200 | 1800 | 1900 | 2300 | 2300 | 2300 |

| Hydraulic Oil-Way Type | / | Open | Open | Open | Open | Open | Open | Open |

| Max. Oil Pressure of Pumping | Mpa | 26 | 28 | 32 | 32 | 32 | 32 | 32 |

| Max. Oil Pressure For Mixing System | Mpa | 8 | 12 | 12 | 12 | 12 | 12 | 12 |

| Max. Mixing Speed | r/m | 24 | 40 | 40 | 40 | 40 | 24 | 24 |

| Capacity of oil tank | L | 150 | 170 | 170 | 600 | 800 | 800 | 800 |

| Max diameter of aggregate | mm | 20 | 30 | 30 | 40 | 40 | 40 | 40 |

| Inside diameter of pipe | mm | 100 / 125 | 100 / 125 | 100 / 125 | 125 | 125 | 125 | 125 |

| Dimension (LxWxH) | mm | 4200x1680x1700 | 4400x1700x1750 | 4400x1700x1750 | 6500x2000x2300 | 6600x1930x2190 | 6800x2100x2350 | 6800x2100x2350 |

| Weight | kg | 3200 | 3500 | 3500 | 6500 | 6800 | 7000 | 7000 |

| Drag speed | km/h | <8 | <8 | <8 | <8 | <8 | <8 | <8 |

Technical Parameters of Electric power concrete Pump

|

Item |

CPE40-10-55 |

CPE60-13-90 |

CPE80-16-110 |

CPE90-18-132 |

CPE90-22-160 |

|

Max. theoretical concrete output capacity (m3/h) |

55 |

65/41 |

86/60 |

88/62 |

95/62 |

|

Total power (kw) |

55 |

90 |

110 |

132 |

160 |

|

Max. aggregate size (mm) |

40 |

40 |

40 |

40 |

40 |

|

Outlet pressure (MPa) |

10 |

13 |

16 |

18 |

22 |

|

Concrete delivery cylinder diameter*stroke (mm) |

Φ200*800 |

Φ200*1600 |

Φ200*1800 |

Φ200*1800 |

Φ200*1800 |

|

Hopper capacity (m3) |

0.5 |

0.8 |

0.8 |

0.8 |

0.8 |

|

Delivery pipe diameter (mm) |

Φ125 |

Φ125 |

Φ125 |

Φ125 |

Φ125 |

|

Concrete slump |

160~220 |

160~220 |

160~220 |

160~220 |

160~220 |

|

Overall dimension (mm) |

4500×1850×1650 |

6000×2100×2250 |

6300×2100×2250 |

6300×2100×2250 |

6800×2100×2250 |

|

Total weight (kg) |

3300 |

5800 |

6200 |

6500 |

6800 |

language

language