Sand making plant is a special production line for producing sand and aggregate materials for construction. In the sand making plant, natural rocks, sandstones, river pebbles and other materials can be processed into artificial sand that meets the requirements of building sand, so as to replace the natural river sand for the buildings and construction industries that need high-quality aggregates. Any kind of material with different hardness grades such as limestone, basalt, granite, dolomite, gabro can be crushed. In addition to sand (fine material) it is also possible to produce other 3 different final fractions simultaneously.

Features of this production line:

1. Complete crushing and screening plant is consisting of one or several crushing and screening units based on the customers' needs.

2. This series of plant is used to crush rocks in the industries such as road construction, building construction, construction materials, water and electricity and civil building etc working with commercial concrete, dry mixed mortar and mixing plant.

3. Core equipment for manufactured sand production line is sand making machine such as VSI crusher, double roller crusher , fine impact crusher ...

4. It is suitable for crushing high quality of basalt, diabase, granite, river gravel, limestone and other hard or medium hard rocks.

5. High production efficiency, regular end product granularity, good grain cubical sand, and low powder content.

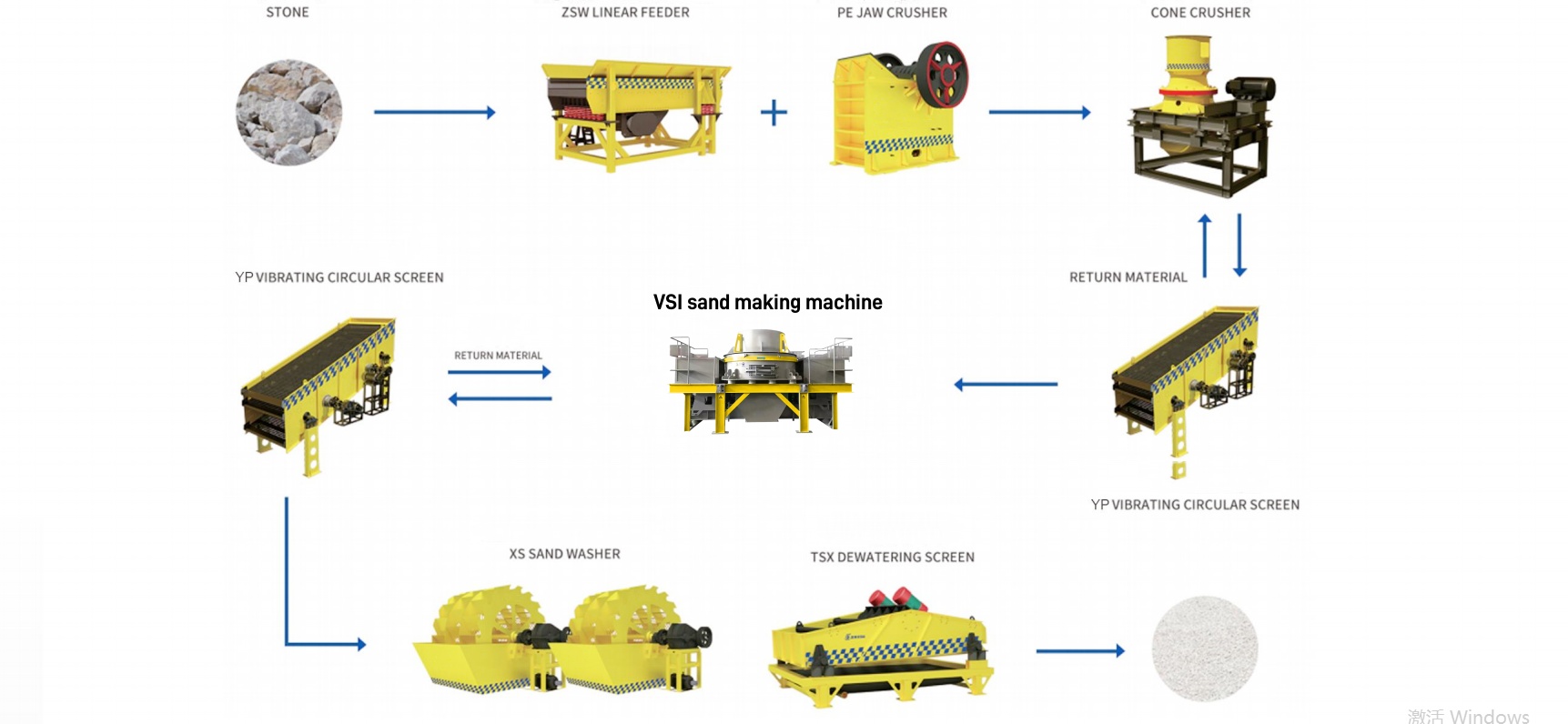

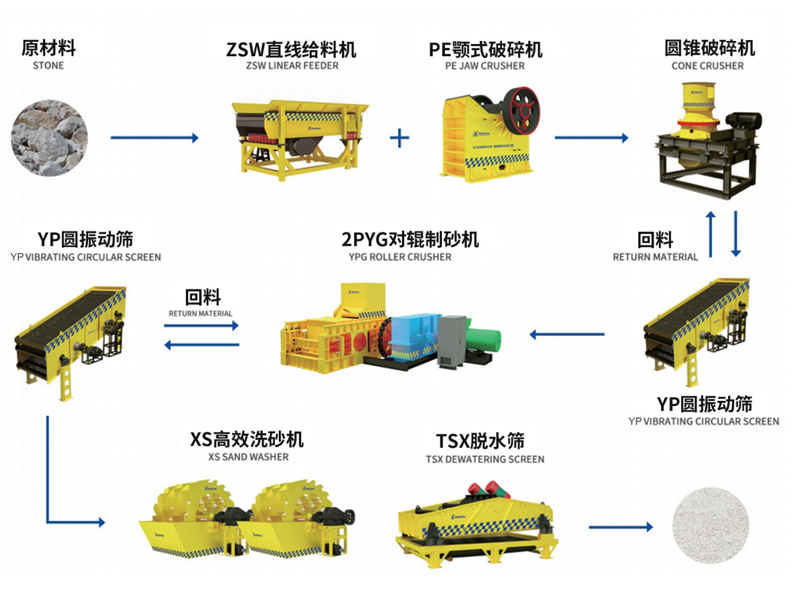

How does sand crusher production line working ?

1.Crush and screen process

Raw stone materials go to Jaw crusher for primary crushing.

Then the materials are transferred by the belt conveyor to secondary crusher ( impact crusher or Cone crusher) for further crushing.

Vibrating screen will grade the materials, where stones that meet the granularity standard will be sent to double roller crusher (or VSI sand-maker), while the rest will be returned to crush again. Materials that don’t meet the required particle size will be sent back to the sand maker for further process or as final aggregate products.

In wet type, the screen could be add a water-spraying system to remove the impurities in advance.

2.Sand washing process

Part of the stones processed by double roller crusher (Or VSI sand maker) will be made into sand and become sand products after being washed by sand washing machine and sand recycling machine. The sand washing machine could choose wheel type or spiral type based on the site situation. Sand dewatering and recycling machine is to help get fine sand and prevent sand loss. Filter machine and sand dryer is optional too according to demand. After the washing process, we get the finished products.

The Equipment List :

No.

Name

Model

Qty

1

Vibration feeder

ZSW380-96

1set

2

Jaw crusher

PE750X1060

1set

3

Cone crusher

PYS1613

1set

4

Vibration screen

3YK1865

1set

5

Double roller crusher

2PYS1810

1set

6

Vibration screen

3YK2465

1set

7

Sand washing machine

XS4030

1set

8

Dewatering screen

TSX2442

1set

9

Belt conveyor

According to the site configuration

Second option :

When crushing hard rock into sand, the core equipment can be a double-roll sand making machine or a VSI sand making machine. The advantage of the double-roll sand making machine is that the parts have a long life and can be replaced for a long time. The advantage of the VSI sand making machine is that the output is large and the particle shape is better. Different configurations can be selected according to the customer's final use.